Solve major Bin Picking applications

3D CPS, a unique robot guiding system that enables you to solve major 3D robot guiding applications. By integrating 3D CPS into your robot cells you will be able to easily handle complex situations.

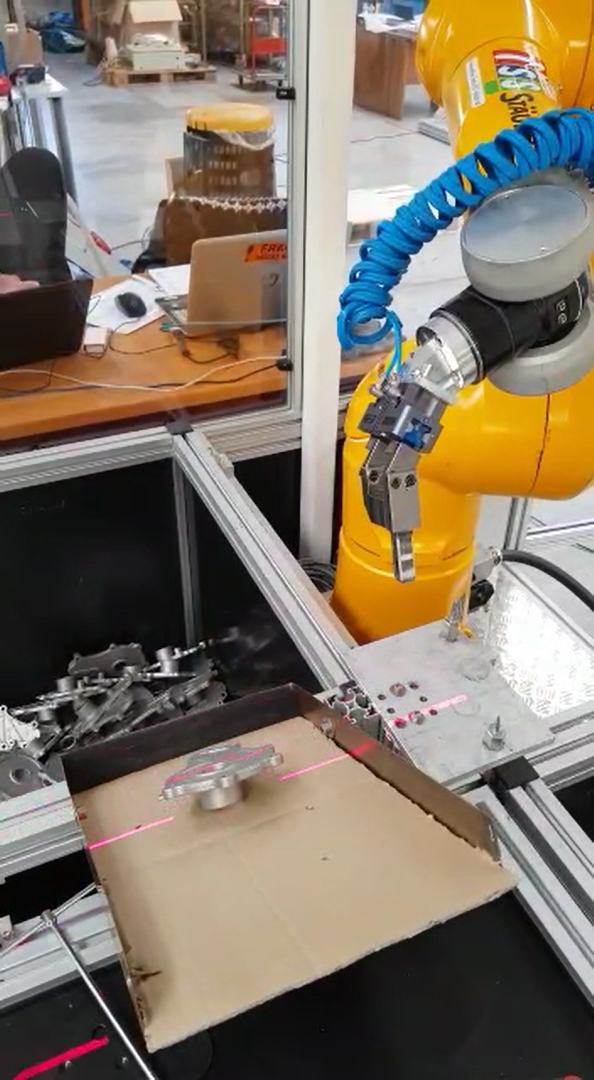

Random Bin Picking

A robot picks up messily arranged pieces inside bins. For it to succeed, the robot must be given the ability to observe, find objects, and choose which one to pick up, how to get to it, and how to get it out of the bin.

3D CPS integrates all these functions internally and benefits from the now more than a decade of development and experience that have enabled the inclusion of numerous features dedicated to solving the anomalous situations inherent in the handling of bulky parts.

Picking from brake discs from a bin is one of the relevant examples, in the video an example of a picking workstation made by G Robotica.

In this case, the versatility provided by the automatic trajectory generator and the ability to handle multiple gripping points make it possible to reach even those parts that are in challenging positions, guaranteeing an excellent level of bin emptying.

Capturing die-cast parts, even small ones, is easily accomplished with 3D CPS due to the high accuracy of the integrated 3D vision system and pattern matching algorithms that enable accurate detection of parts even if they are only partially visible.

Handling several grip poses on the workpiece allows for a compact gripping tool and thus reach even the peripheral areas of the bin.

Semi-ordered Bin Picking with interlayers

The 3D vision system makes it easy to identify the parts arranged on the layers, even if they are in abnormal positions compared to the nominal position, easily handles the variable part dimension according to the layer being processed.

In this application, made by Tecnosystem using 3D CPS 4.0 L, parts arranged on an interleaf are free to tilt more than 20°: with 3D CPS, it is possible to locate the position of the part accurately and pick it up correctly.

The automatic trajectory generator further simplifies the work as the path to reach each part is generated automatically: the robot only needs to execute each path provided to reach all the parts.

Semi-ordered Bin Picking without interlayers

Often parts are stacked or arranged in an order that is not fully defined within bins. Thanks to 3D CPS, however, a robot can handle this type of scenario effectively. Not completely defining the position of parts is not a problem because they are fully identified in space and handled appropriately with specific functions (sorting in order of height of identified parts).

3D Localization

3D CPS also allows the location of a single part in space. This function can be used for different purposes, for example, accurate identification of the position in space of a single part on tape (useful in all cases where a 2D system cannot identify a part, such as a part with burrs, or in case of installation in a poorly cleaned environment), the resumption of a part after picking it up from caisson.

Palletizing

3D CPS systems can also be used in some special palletizing cases: for example, they can be used to deposit parts on shaped interlayers. In fact, 3D CPS can identify the position of the deposit and then generate the collision-free path that allows the part to be brought to the correct unloading position.