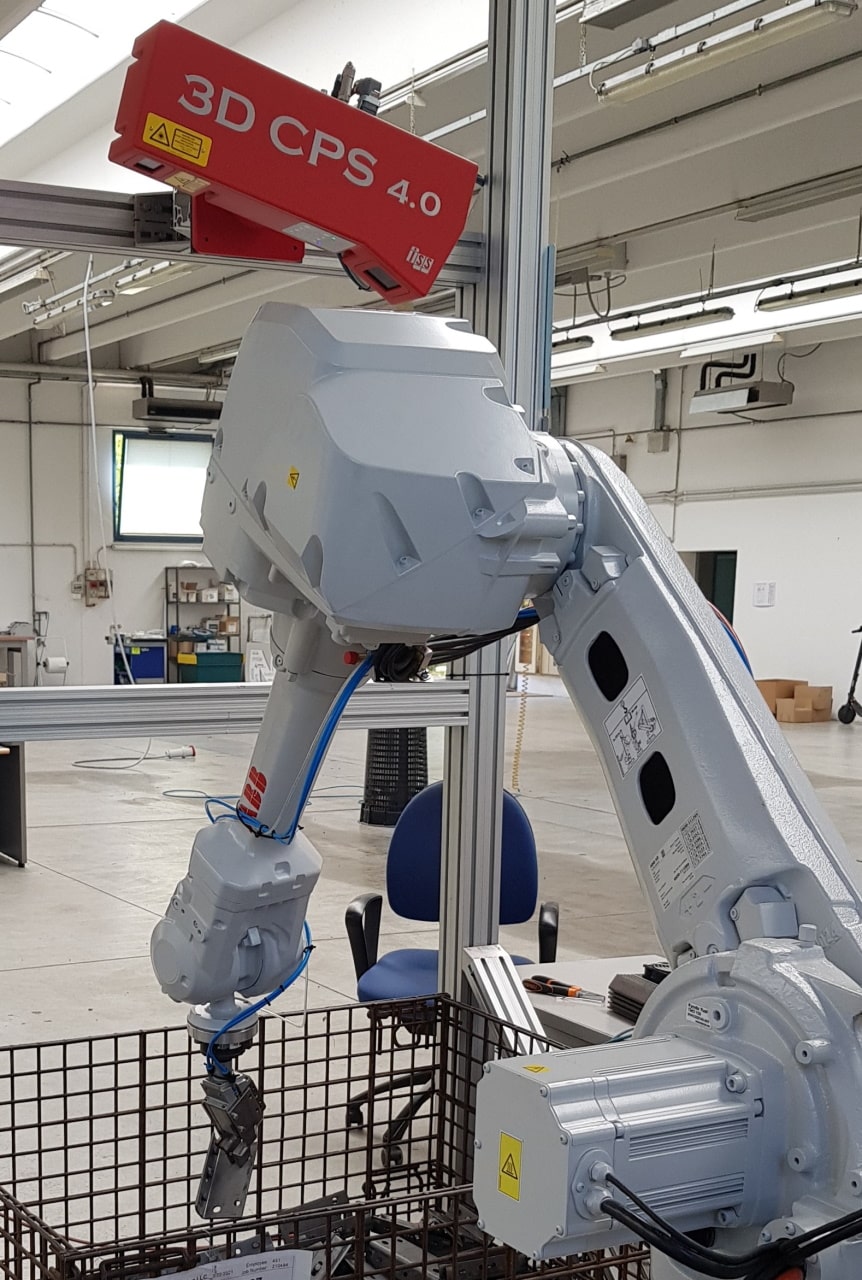

Courtesy of G.Robotica

Robotic, Autonomous, Fast and Effective Systems

Currently, the automation of loading of operating machines is done either using a completely flexible tool, the robot, or an extremely rigid mechanical auxiliary machine. The robot can position the wrist anywhere in the working volume with an arbitrary orientation, while an auxiliary machine, usually composed of vibrators equipped with trap paths, is designed to position and orient a single component, in a known position. This rigidity, combined with the need to shake the parts to move them by generating micro-bumps between them and the considerable bulk of such equipment, make this approach a suboptimal solution.

The implementation of a system capable of picking up randomly oriented parts by means of an anthropomorphic manipulator would overcome such problems and provide an extremely effective tool in the quest for production process optimization.

The earliest examples of direct bin picking date back to the late 1990s, several times applications were presented that effectively accomplished “Bin Picking” on simple parts. Despite these attempts and more than two decades later, Bin Picking remains one of the greatest challenges in the field of vision applied to robotics.

So, what is the reason that has prevented the large-scale deployment of a solution that offers such great advantages? Analysis of the problem and experience have shown that there are many obstacles to overcome:

- difficulty in recognizing the part

- lack of flexibility in learning new parts to recognize

- overlapping of the parts to be picked up

- interference between the parts in the bin, the robot and the gripper

- difficulty in reaching the gripping point caused, for example, by the orientation of parts.

The presence of such a complex set of problems that require an extremely broad spectrum of expertise to be addressed has placed serious limits on the deployment of bin picking systems, discouraging many integrators, who do not have such a broad knowledge base to propose sufficiently reliable and flexible solutions of this type. Although a universal solution to the problem is, at present, almost impossible to achieve, a careful analysis of the individual problem and an appropriate choice of technological solutions can lead to success in an extremely large number of cases.

3D CPS was developed with the aim of offering the robotic system integrator a tool capable of autonomously handling all the problems exposed thus enabling the development of Bin Picking applications autonomously, quickly and effectively.

The 3 skills of the 3D Robot Guide

1. 3D Vision

ISS has independently developed the 3D vision systems on which the CPS 3D robot guides are based, deploying various measurement techniques. Customers therefore have a wide range of products to solve different applications by being able to take advantage of the most suitable technology. In particular, the 3D CPS systems of the 4.0 family take advantage of a laser profilometry system that guarantees optimal performance over very large work volumes, while the 3D CPS FAST systems take advantage of a system based on stereoscopy and structured light that combines excellent accuracy with high scanning speed over small work ranges.

The choice of self-developed systems also allows ISS to have full control over all elements of the system and to be able to focus its development according to the specific needs of Bin Picking.

2. Recognition of elements

The “3D CPS Configurator” application is the program that, in a few simple steps, allows the 3D CPS to be configured, indicating to the system the arrangement of the parts disposed inside the bin and the picking strategies to be used.

The user will also be able to provide a virtual reconstruction of the robot’s working environment, allowing the system to have all the information to then calculate the paths that the robot will have to execute in order to get to grasp the parts arranged inside the bin without causing collisions with surrounding bodies.

The program guides the user step by step until the device is fully and properly set up. In fact, it is possible to simulate offline a work cycle of the 3D CPS to evaluate processing results and proceed to optimize operating parameters.

The result of the configuration process is a simple recipe file. Depending on the production requirements, it will only be necessary to select the correct file to be used. This makes the 3D CPS a perfectly reconfigurable and flexible product that can drastically reduce the cost and time of format changeover.

3. Trajectory generation

The 3D CPS Planner software is the tool that allows the user to evaluate the results of all major functions of 3D CPS. Outputs from the stages of part recognition and trajectory generation can be analyzed.

Sophisticated trajectory calculation algorithms make it possible to generate the paths that allow the robot to reach the recognized parts and pick them up from the bin with maximum reliability. The system not only generates reliable paths that exclude collisions with the surroundings, but also allows the generation of trajectories that prioritize simplicity and linearity of movements.

If for a recognized part it is not possible to generate a collision-free trajectory, the system is able to show the user the reasons for the failure to generate the trajectory, thus allowing the user to assess whether the problem is due to an incorrect configuration of the planning parameters or a real physical impossibility of picking up the part. All of this in order to guide the user to ensure that the bin is as empty as possible.

Fields of application

The manufacturing industry is increasingly looking for solutions in the field of process automation to increase efficiency and reduce production costs. Bin Picking is certainly one of the applications on which the greatest attention of automation specialists in various fields is focused: